The U.S.–China Scrap Metal Loop Makes No Sense — ECOLIT Offers a Smarter Alternative

Every year, the United States accumulates over 12 million junk cars. Most people assume these vehicles get recycled domestically. In reality, a surprising amount of scrap metal is shipped overseas — mainly to China — where it’s melted down, turned into steel, and later sold back to the U.S. as finished products.

It’s a strange and wasteful loop:

American cars → exported as scrap → processed abroad → imported again as metal.

This system carries obvious problems — high emissions, lost economic value, and dependence on foreign recycling. And while millions of tons of steel leave the country, the U.S. struggles with an affordable housing shortage and rising climate-related risks.

ECOLIT is trying to change this picture.

Instead of exporting the waste, ECOLIT proposes keeping it in the country and turning it into something people truly need: disaster-resistant homes.

The company’s engineering team found that steel from three end-of-life vehicles is enough to produce one complete structural frame for an ECOLIT home kit. Their system combines cold-formed steel (CFS) with fire-safe foam-concrete panels — materials that outperform traditional wood in durability, fire resistance, moisture protection, and hurricane performance.

In other words, junk cars become high-value housing, not low-value scrap.

Why this approach works?

By recycling domestically instead of exporting, the ECOLIT model:

✅ reduces transportation emissions,

✅ saves money on raw steel,

✅ supports local manufacturing,

✅ brings construction materials directly to communities that need them.

The contrast is especially striking in major cities. For example, New York collected roughly 100,000 junk vehicles in the past two years — while more than 100,000 residents lack stable housing. It’s a missed opportunity hiding in plain sight.

Stronger Homes, Stronger Communities

ECOLIT’s panels have been tested internationally, withstanding temperatures up to 2000°C and staying stable after hours of direct fire exposure. The lightweight steel frames also perform well against hurricanes and earthquakes, offering significantly higher safety margins than wood construction.

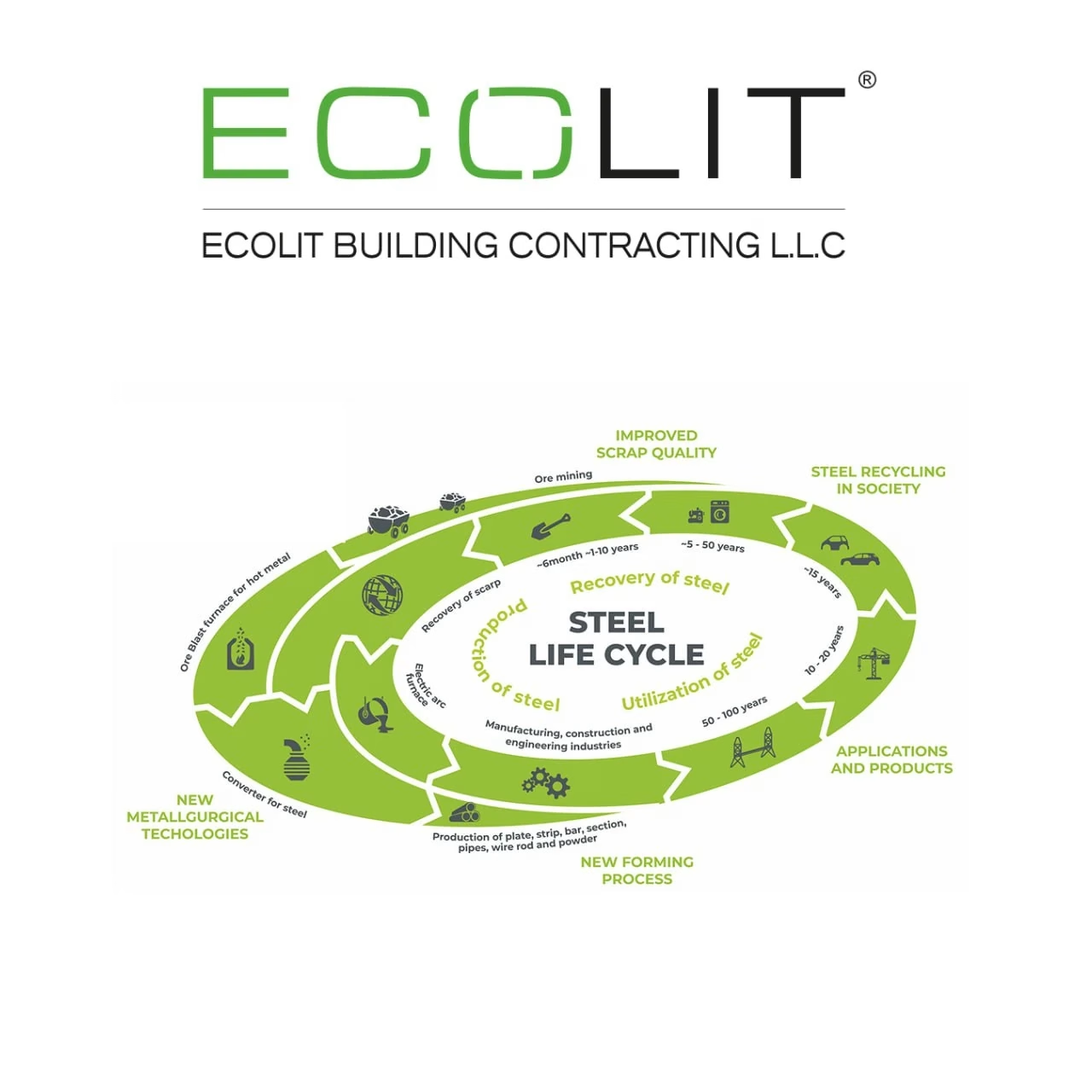

Recycled steel doesn’t diminish performance. Once processed, it becomes identical to new material — but with a much smaller environmental footprint.

Closing the loop at home

The U.S.–China scrap cycle belongs to the past. ECOLIT’s initiative suggests a far simpler loop:

retired cars → recycled steel → ECOLIT frames → affordable homes.

It’s local, sustainable, and aligned with real community needs. Instead of exporting a problem, ECOLIT turns it into a solution — and a strong one.