ECOLIT LAUNCHES CAR RECYCLING PROGRAM

Every recycled car means one less landfill — and one more sustainable project built.

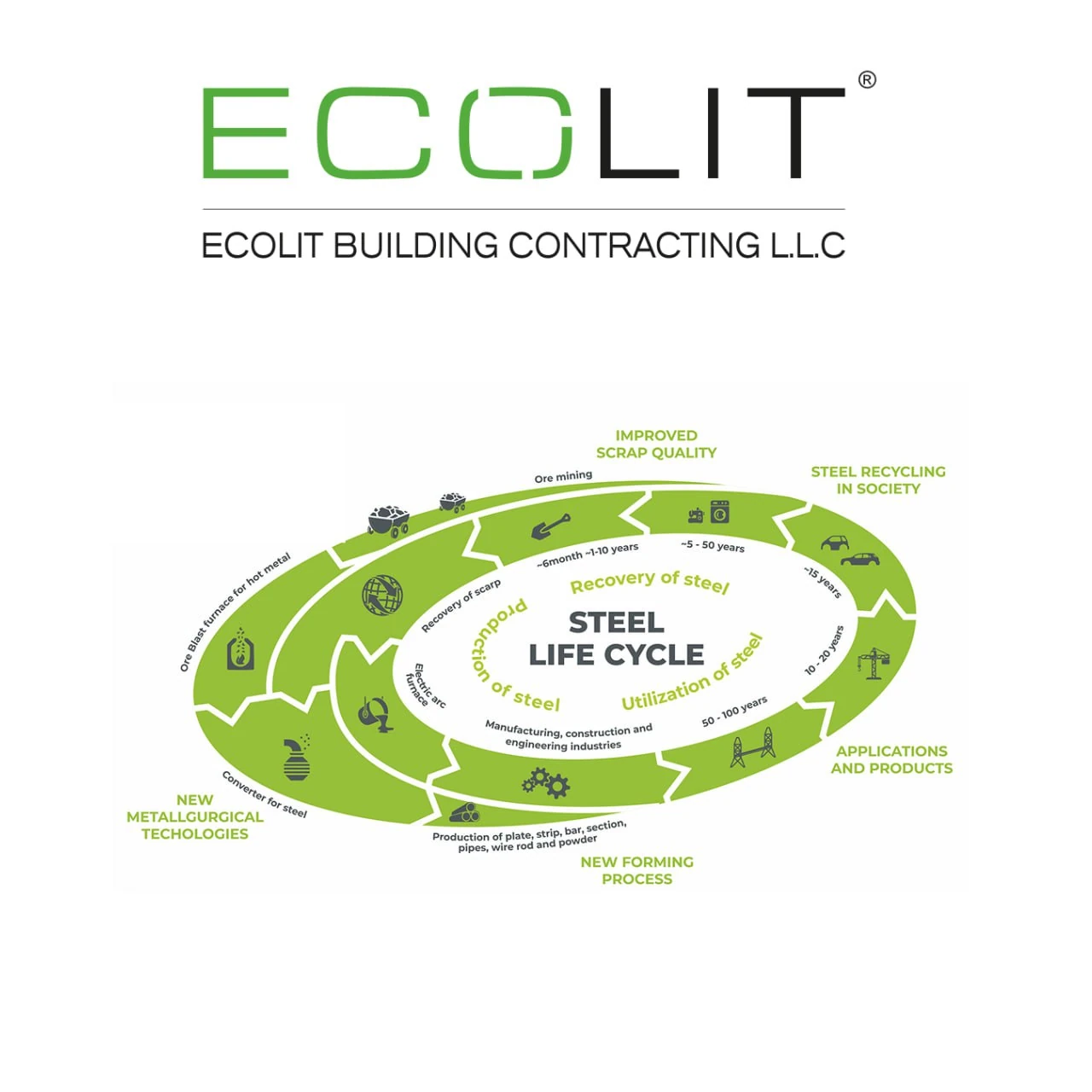

From vehicle to building: the recycling path

Each year, more than 27 million vehicles are retired worldwide. Many end up in landfills, polluting the environment. At ECOLIT, we transform this steel into the backbone of new buildings.

The process step by step:

1. A vehicle is dismantled

2. Steel is sorted and extracted

3. Cleaned and milled

4. Cut into structural parts

5. Formed into precise LGSF modules

6. Assembled into houses, pavilions, or public buildings

Every recycled car equals one strong, sustainable frame for future construction.

Why LGSF is the future of building

LGSF (Light Gauge Steel Framing) represents a new generation of construction:

• Digitally designed with high precision

• Manufactured with zero waste

• Based on circular material usage

• Adaptable to any climate or terrain

This is not just another method — it is a revolution in green building.

Quality without compromise

Recycled steel is held to the same standards as new steel.

Every LGSF module undergoes rigorous testing, including:

• Structural strength

• Fire resistance

• Moisture and salt exposure

• Wind load performance

Smaller footprint, greater impact

Traditional materials like concrete and brick leave a heavy carbon footprint.

By using steel from decommissioned cars, we reduce environmental impact significantly:

• No need for virgin steel production

• Lower transport requirements

• No heavy machinery on-site

The result is up to 40% fewer CO₂ emissions compared to conventional building methods.

Smart business, not just smart ecology

LGSF is not only eco-friendly but also economically efficient:

• Lower production costs with recycled inputs

• Faster ROI due to shorter construction times

• Minimal logistics and waste

• Increased consumer trust in sustainable products

• Full ESG compliance for modern companies

In LGSF, ecology meets economy.

Expanding the material palette

Beyond steel, ECOLIT integrates next-generation materials such as foam concrete.

It is lightweight, energy-efficient, and free of high-emission firing processes. Combined with LGSF, it provides greater efficiency, easier logistics, and reduced environmental impact.

People behind the process

Behind every recycled car-turned-building is the ECOLIT team: engineers, modelers, architects, and construction crews. Together we unite ecology, engineering, and construction into a seamless, scalable system.

Conclusion

Every recycled vehicle is more than just waste avoided — it is the foundation of sustainable architecture.

At ECOLIT, we do not just recycle steel. We reimagine the future of construction.