Dubai, United Arab Emirates — June 2025

ECOLIT Building Contracting L.L.C has officially achieved three major international certifications, marking an important milestone in the company’s growth and commitment to global standards of quality, safety, and sustainability.

Certified by LEMS Quality & Standardization Certificates Issuing Services, ECOLIT has been independently assessed and found compliant with the following international standards:

ISO 9001:2015 — Quality Management System

Recognizes ECOLIT’s dedication to consistent product quality, customer satisfaction, and continuous improvement across all processes.

ISO 14001:2015 — Environmental Management System

Confirms the company’s responsible approach to environmental impact, resource management, and sustainable construction practices.

ISO 45001:2018 — Occupational Health & Safety Management System

Demonstrates ECOLIT’s firm commitment to maintaining safe working environments, proactive risk management, and employee well-being.

All certificates were issued in Dubai, UAE, with the assessment conducted in compliance with ISO 17021:2015 standards under the supervision of Accreditation Service for Certification Bodies (ASCB), United States.

“These certifications are more than a formality — they’re a recognition of the systems and discipline behind every ECOLIT project.

From structural integrity to workplace safety and environmental stewardship, we’re proud to meet the world’s highest benchmarks,”

— Denis Lozenko, Founder & CEO, ECOLIT.

The certifications apply to steel construction contracting, building contracting, and lightweight concrete screeding, further reinforcing ECOLIT’s position as a trusted name in modular and sustainable construction.

Setting the foundation for global growth

ECOLIT continues to expand globally, from the United States to the Caribbean and the Middle East, providing high-efficiency steel framing systems for residential and commercial projects worldwide.

These ISO achievements lay the groundwork for future large-scale partnerships and demonstrate the company’s readiness to operate under internationally recognized frameworks of excellence.

New Times Magazine has published an exclusive interview with Denis Lozenko, CEO of ECOLIT — the company that’s redefining the way we think about construction. ✨

Their buildings are made of galvanized steel (lasting over 70 years) and lightweight foamed concrete, which provides exceptional thermal and sound insulation. These structures can withstand earthquakes up to magnitude 9 and winds up to 250 mph.

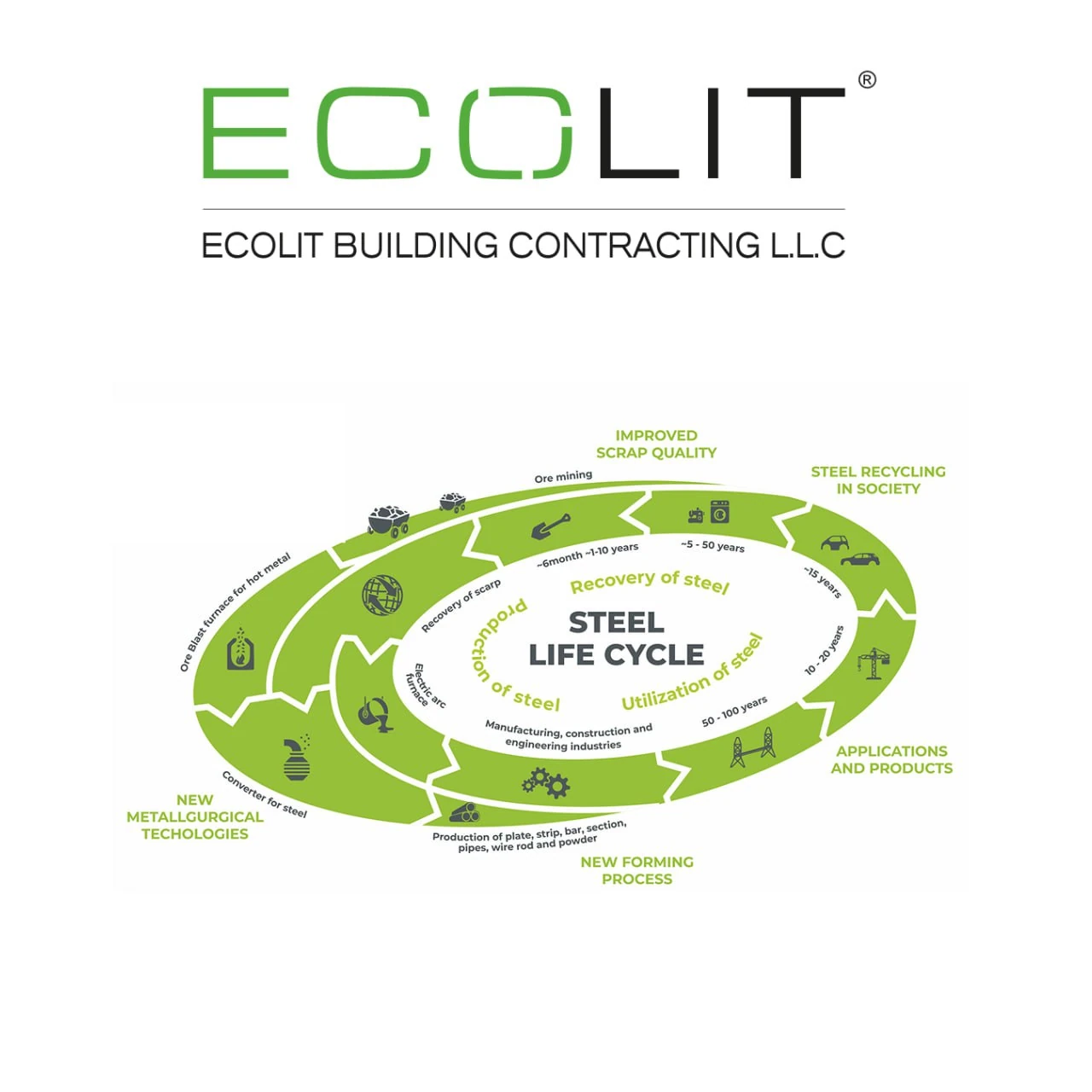

The core idea behind ECOLIT is to make high-quality housing affordable — without compromising on safety or sustainability. Producing a 1,000 sq. ft. home consumes less than $100 worth of electricity, and 90% of the steel comes from recycled vehicles.

ECOLIT is not just a technology — it’s a new standard for sustainable, fast construction, where housing becomes more accessible and the planet cleaner.

Read the full article about how ECOLIT turns innovation into the new reality of construction:

ECOLIT has reached a defining milestone: after 305 revisions and more than 18 months of dedicated work, we proudly announce that our construction system has received its first official permit in the United States. The approval was granted in Sacramento, California, marking the beginning of a new chapter for sustainable and innovative building technologies in North America.

The approved solution integrates lightweight concrete insulation with a cold-formed steel framing system, combining strength, energy efficiency, and speed of construction. This recognition confirms that ECOLIT’s technology not only meets but exceeds modern U.S. construction standards, offering developers and communities a smarter alternative to traditional building methods.

For ECOLIT, this permit represents more than a document — it is proof of our long-term vision. From the very beginning, our mission has been to make sustainable, cost-effective, and safe construction accessible worldwide. With over 17 years of experience, projects in 19 countries, and a growing network of partners, ECOLIT continues to prove that innovation and responsibility can go hand in hand.

Our journey in California is only the start. Next on our roadmap are Los Angeles and San Diego, with further expansion planned into Illinois, Ohio, Arkansas, Texas, Florida, and New York. Each step brings us closer to redefining construction across the United States.

This achievement would not have been possible without the persistence of our team and the trust of our partners worldwide. Together, we are shaping a future where buildings are faster to erect, stronger to withstand seismic risks, and greener for generations to come.

To explore partnership opportunities in the U.S. or beyond, call us at +1 (279) 226-2397 or contact us directly through our website.

The future of sustainable construction is here — and it’s ECOLIT.

ECOLIT is expanding its international partnership program and invites companies, developers, and private investors to join in shaping the future of sustainable construction.

The demand for fast, reliable, and eco-friendly building solutions is growing worldwide. ECOLIT provides technologies and expertise that meet these challenges and set new standards for urban development.

• LGSF construction — lightweight, durable, and earthquake-resistant steel frames

• Prefabricated and modular homes in the USA using eco-friendly materials

• Sustainable concrete and advanced recycling technologies

• Tiny house and small home projects for residential and commercial use

Our partners receive:

• Expert consultations and help in choosing optimal solutions

• Equipment warranty and reliable service

• Training and technical support at every stage

By joining ECOLIT, you become part of a global movement to make construction faster, greener, and more resilient. Together, we are building a future where homes are safe, sustainable, and accessible.

ECOLIT’s CEO, Denis Lozenko, met with New York City Mayor Eric Adams at City Hall — a historic place where the future of the metropolis is shaped.

At the meeting, Denis Lozenko presented the ECOLIT program and discussed how innovative construction technologies can support the development of New York’s urban environment: making it more advanced, sustainable, and accessible.

The dialogue focused on practical solutions: faster and more efficient building systems, energy-efficient housing, and approaches that match the city’s ambition to remain one of the world’s most dynamic urban centers.

This visit was more than a formal introduction. It became a step toward international cooperation and a contribution to the global conversation about the future of cities.

We thank the team for their preparation and support. For ECOLIT, this is only the beginning.

In Sunny Isles Beach, ECOLIT’s CEO, Denis Lozenko, met with the city’s mayor, Larisa Svechin.

Here, “Height of Life” is more than just a slogan: skyscrapers soar over 70 stories, offering a high standard of living and the most expensive real estate in Florida.

But even in such a unique city, challenges remain: annual hurricanes, flooding, and costly repairs, with insurance not always covering the damage. New buildings are now being constructed three feet higher to reduce the risk of flooding.

ECOLIT takes on this challenge by applying technologies that make construction truly resilient.

Every recycled car means one less landfill — and one more sustainable project built.

From vehicle to building: the recycling path

Each year, more than 27 million vehicles are retired worldwide. Many end up in landfills, polluting the environment. At ECOLIT, we transform this steel into the backbone of new buildings.

The process step by step:

1. A vehicle is dismantled

2. Steel is sorted and extracted

3. Cleaned and milled

4. Cut into structural parts

5. Formed into precise LGSF modules

6. Assembled into houses, pavilions, or public buildings

Every recycled car equals one strong, sustainable frame for future construction.

Why LGSF is the future of building

LGSF (Light Gauge Steel Framing) represents a new generation of construction:

• Digitally designed with high precision

• Manufactured with zero waste

• Based on circular material usage

• Adaptable to any climate or terrain

This is not just another method — it is a revolution in green building.

Quality without compromise

Recycled steel is held to the same standards as new steel.

Every LGSF module undergoes rigorous testing, including:

• Structural strength

• Fire resistance

• Moisture and salt exposure

• Wind load performance

Smaller footprint, greater impact

Traditional materials like concrete and brick leave a heavy carbon footprint.

By using steel from decommissioned cars, we reduce environmental impact significantly:

• No need for virgin steel production

• Lower transport requirements

• No heavy machinery on-site

The result is up to 40% fewer CO₂ emissions compared to conventional building methods.

Smart business, not just smart ecology

LGSF is not only eco-friendly but also economically efficient:

• Lower production costs with recycled inputs

• Faster ROI due to shorter construction times

• Minimal logistics and waste

• Increased consumer trust in sustainable products

• Full ESG compliance for modern companies

In LGSF, ecology meets economy.

Expanding the material palette

Beyond steel, ECOLIT integrates next-generation materials such as foam concrete.

It is lightweight, energy-efficient, and free of high-emission firing processes. Combined with LGSF, it provides greater efficiency, easier logistics, and reduced environmental impact.

People behind the process

Behind every recycled car-turned-building is the ECOLIT team: engineers, modelers, architects, and construction crews. Together we unite ecology, engineering, and construction into a seamless, scalable system.

Conclusion

Every recycled vehicle is more than just waste avoided — it is the foundation of sustainable architecture.

At ECOLIT, we do not just recycle steel. We reimagine the future of construction.

ECOLIT held a demonstration of our technology, which included a workshop so participants were able to touch, feel and experience the equipment and material. Attendees included Architects, Engineers, Managers and Owners of ECOLIT operations anticipating delivery of their equipment within the coming months. ECOLIT is global and our outreach came from as far away as Guyana South America, with other participants in the USA from Houston Texas, Chicago Illinois, New York, plus other locations.

Congratulations are in order on the opening of ECOLIT’s first (1st) Thailand Production Facility in Phuket. Upon the arrival of the systems in Phuket, and unpacking commencing, the ECOLIT Team simultaneously attended the Bangkok Thailand “Architect’68” Trade Show.

The demand for fast, reliable, and eco-friendly building solutions is growing worldwide. ECOLIT provides technologies and expertise that meet these challenges and set new standards for urban development.

A huge show of interest was displayed by a large number of attendees at the show, leaving the ECOLIT Team with a significant amount of follow-up work after their first (1st) of many future exhibitions.

Today, ECOLIT is gaining significant distribution channels and offices throughout the Asian market. We are excited to open our first (1st) office and first (1st) production facility in Thailand, following on the heels of a number of major production facilities, and construction projects, currently under way in Indonesia.

ECOLIT can also confirm a second Thailand office with a production facility will open in Bangkok Thailand.

ArchiBuild Expo, supported by the Australian Institute of Architects, is Australia’s leading event for architects, designers and builders, showcasing cutting-edge products and solutions for the future of our built environment.

ECOLIT CONSTRUCTION SYSTEM AU PTY LTD will be at Melbourne Convention and Exhibition Center from 12-14 June 2025 where we will be part of the 200+ leading suppliers, plus a networking group of 12,500+ design and build professionals.